Can you confidently

converse with joiners?

Picture this: A scenario I’m 99% certain we all have been in at one stage in our careers.

You’re on the phone with a joiner—that part sounds fun, right?

But let’s turn up the heat.

You’re on the phone in an open-plan office with other designers within earshot.

The joiner wants to finalise a few details with you on the phone.

They are finishing off a unit that is about to be sprayed. During the conversation, they drop in a few unknown terms you have never heard of before. You close your eyes, trying to visualise exactly what they are explaining.

Your anxiety starts rising, you’re confused, and you don’t want to ask:

Urm, sorry, can you explain to me what a quirk is?

Side Note: You generally love to ask questions, but today, you’re in the open-plan office and want to avoid the rest of the office questioning your experience and street cred.

Do you consider yourself a wordsmith of the native joinery dialect?

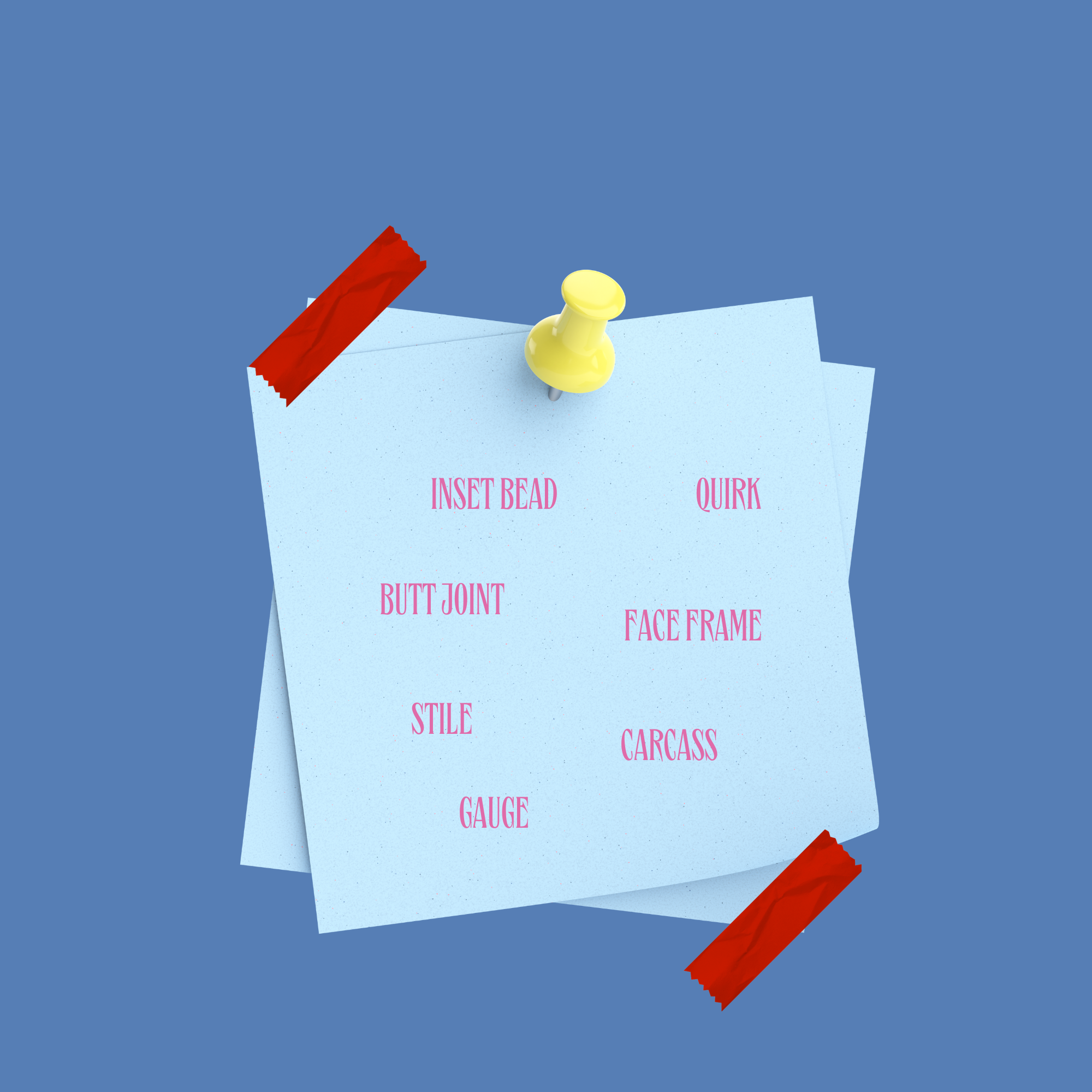

Joinery lingo cheat sheet:

Applied moulding: Decorative moulding applied to the face of the door/drawer.

Bead: A small decorative profile or moulding that is applied. It can be functional to help cover joints or seams or decorative to add texture or detail to plain surfaces.

Bespoke: Something custom-made or tailored to an individual’s specific requirements and preferences, e.g. bespoke kitchen design tailored to the exact requirements of the designer/client. Bespoke and custom are the same thing.

Above: A applied bobbin bead, that has been finished in 2PAC polyurethane.

Biscuit (Joint): A woodworking technique where an oval-shaped wooden biscuit is inserted into corresponding slots in two adjoining pieces of wood, enhancing alignment and providing additional strength to the joint when glued together

Butt Joint: A butt joint is a simple woodworking joint where the ends of two pieces of wood are joined by placing them perpendicular to each other and securing them with adhesive, nails, screws, or dowels

Cabinet Box: This is the basic structural framework of a cabinet, typically consisting of top, bottom, side, and back panels, onto which doors, drawers, and other components are attached.

Carcass: The main structural framework or skeleton of a piece, onto which other components such as doors, drawers, and panels are attached.

Above: The wardrobe carcass during installation. This was constructed from Laminex Kalamata. Completed photo to the left by Jacqui Turk.

Caulk: An elastomeric sealant to fill/hide gaps between joints or seams in woodwork, providing a seamless appearance and enhancing structural integrity by preventing moisture infiltration.

Custom: Something custom-made or tailored to an individual’s specific requirements and preferences, e.g. bespoke kitchen design tailored to the exact requirements of the designer/client. Bespoke and custom are the same thing.

Drawer Box: The inside of the drawer which creates the storage space

End Panel: The decorative panel covering the exposed end of any base or wall cabinet.

Expansion Joint: A deliberate gap left between two adjoining pieces of wood to accommodate natural wood movement due to seasonal changes in humidity or temperature, preventing warping or cracking.

Fabrication: This is the process of constructing or assembling wooden components and structures according to specific designs or requirements, often involving cutting, shaping, joining, and finishing operations.

Face Frame: This is common in historic joinery. In cabinetry, a face frame refers to a structural framework attached to the front edges of cabinet carcasses, providing support, reinforcement, and a mounting surface for hinges and drawer slides.

Filler panel: A thin material that fills the gap between two more significant components or structures. Filler panels are commonly used when an uneven or irregular gap exists between cabinets, appliances, or other joinery elements. They help to create a seamless appearance by covering the space and providing a consistent surface.

Frameless construction, also known as full-overlay construction, is a modern method that differs from framed joinery in that it involves designing cabinets without a front face frame.

Framed joinery: This is a historic technique in which structural frames are constructed and used to support and encase panels, doors, or other components, providing stability and visual definition in furniture or cabinetry construction.

Above: Plain English framed joinery. The structural frames are clearly visible, providing structural support. The hinges and drawers are then fitted to the structure.

Gauge: In the context of metal, a “gauge” refers to the thickness or diameter of a metal sheet or wire. Typically represented by a numerical value, the higher the gauge number, the thinner the metal.

Grade: In joinery, “grade” refers to the quality and standard of a component, like timber/wood products. Grades are assigned based on appearance, strength, durability, and suitability for specific applications. Higher grades mean better quality and often higher prices, while lower grades may have more imperfections or lower performance.

Grain: Refers to the direction, pattern, and texture of wood fibres visible on the surface of a piece of wood, influencing its appearance, strength, and workability.

Inset is a style where cabinet doors and drawers are flush with the face frame, creating a seamless and traditional appearance.

Inset bead refers to a decorative moulding or profile recessed into the surface of a frame or panel, adding visual interest and detail to the design.

Jigs act as templates or guides that help the joiner. By using a jig, joiners can achieve consistent results and save time by eliminating the need to measure and mark each piece. Jigs can be designed for specific tasks, such as cutting dovetail joints, drilling pocket holes, or routing particular profiles

Kicker, kick, kickboard: Used for a few purposes:

1) They provide ergonomic benefits by allowing users to stand closer to the bench or countertop and comfortably tuck their feet underneath.

2) They conceal the framework of the joinery, especially when adjustable feet systems are used to support the carcasses and help accommodate uneven floors

3) Are essential for integrated appliances like fridges and dishwashers, where the manufacturers have produced the appliances to work with a kicker detail or require ventilation through the kicker

Millwork is the American term for joinery.

Mitre Joint is created by joining two pieces of wood together at an angle, typically 45 degrees, to form a corner. It is often used in frames and trim work for its clean and seamless appearance.

Mullion or Munton: The cross bars installed in an open frame door give the door the look of window panes. It can also be the centre stile or rail in a multi-panel door.

Nesting is the process of optimising the placement of different parts or components of a project onto a single sheet or board of material. It involves arranging and positioning the individual pieces to minimise waste and maximise material utilisation.

Above: Examples of nesting via CNC machine to maximise material yield.

Overlay (full overlay): A door that entirely covers the carcass.

Plant on: Attaching or affixing an additional component to an existing structure to modify or enhance its appearance, such as applying mouldings to a joinery door.

Profile: In joinery, the term “door profile” refers to the shape or design of a door’s cross-sectional view. A flat profile, a shaker profile…

Quirk is a minor, recessed groove or channel typically cut into the edge or face of a board, often for decorative purposes or to facilitate fitting other components.

Rail, the horizontal member of a door frame.

Rebated, in joinery, the term “rebated” refers to:

1) Creating a groove or recess along the edge of a wooden piece to allow another piece to fit into it, forming a flush and secure joint.

2)Removing a portion of the material to create a recess (rebate) in the door profile.

Return refers to the continuation of a moulding or trim piece beyond its original termination point, often to provide a finished appearance or to wrap around a corner.

A router is a power tool used to hollow out, shape, or cut grooves in wood by spinning a cutting bit at high speeds. It offers versatility for various shaping and joinery tasks.

CNC ROUTER: Production router that is CNC controlled.

Scribe refers to the process of fitting or shaping a piece of material to match the contours or irregularities of an adjacent surface. Scribing aims to create a seamless and tight joint between two or more components.

Shadowline/shadow gap in joinery, a shadow gap is a small, intentional gap or recess between two adjacent surfaces, typically used for aesthetic purposes. It creates a subtle shadow line, adding depth and visual interest to the joinery. The width of the shadow gap can vary depending on the desired aesthetic effect (10 or 20mm is very common).

Shaker is a door profile consisting of a “frame” around the centre of the door. Shaker frames vary in width from 60mm, considered traditional, to a slimline of around 15mm.

Span is the distance or length between two supporting points or structures. Joiners add uprights or other structural components to maintain structural integrity. Often, they may ask to install an upright in a wardrobe to ensure the shelving can take the clothing load (i.e., stop bowing / warping).

Stile is the vertical member of a door frame.

Warp/Warping is the deformation or distortion of joinery elements. It occurs when the material undergoes changes in shape, such as bending, twisting, or cupping, due to lack of structure in the board (incorrect thickness used), uneven drying, changes in moisture content, or other environmental factors.

Comments +